Have you ever wondered what makes gold such a valuable and sought-after metal? The answer lies in the fascinating world of gold alloys. These magical combinations of gold with other metals create a variety of colors, strengths, and properties that have captivated artisans and scientists for centuries.

In this article, we delve into the alchemy of gold alloys and explore the secrets behind their allure. We will uncover the art and science behind the meticulous process of mixing gold with metals such as copper, silver, and palladium to create captivating hues like rose gold, white gold, and green gold.

Why are Gold Alloys Used?

Gold alloys are used for a variety of reasons. While pure gold is beautiful and valuable, it is also soft and malleable, making it less suitable for certain applications. By combining gold with other metals, we can enhance its strength and durability, making it more practical for everyday use.

Additionally, gold alloys offer a wider range of colors and appearances than pure gold. This allows jewelry designers to create unique and eye-catching pieces that cater to individual preferences. From the warm and romantic tones of rose gold to the sleek and modern look of white gold, gold alloys offer endless possibilities for creative expression.

Types of Gold Alloys

There are several types of gold alloys, each with its own unique composition and properties.

The most common Gold Alloys types include:

1) Rose Gold Alloy

Rose gold is created by adding copper to gold. The copper gives the alloy a warm, reddish hue, reminiscent of a romantic sunset. This rose gold alloy has gained popularity in recent years for its vintage appeal and ability to complement a wide range of skin tones.

2) White Gold Alloy

White gold is made by combining gold with white metals such as nickel, palladium, or silver. This alloy of white gold has a silvery appearance, similar to gold platinum alloy, and is often used as a more affordable alternative to platinum jewelry. However, it is important to note that white gold is usually coated with rhodium to enhance its whiteness.

3) Green Gold Alloy

Green gold, also known as electrum, is a naturally occurring alloy of gold and silver. It has a greenish-yellow color and was historically used to create coins and jewelry. Green gold has a unique appearance that adds a touch of elegance and sophistication to any piece.

Properties of Gold Alloys

Gold alloys inherit properties from both gold and the metals they are mixed with. Here are some key properties of gold alloys:

Hardness: Gold alloys are harder and more durable than pure gold, making them less prone to scratches or dents. The hardness of an alloy depends on the metals added and their proportions.

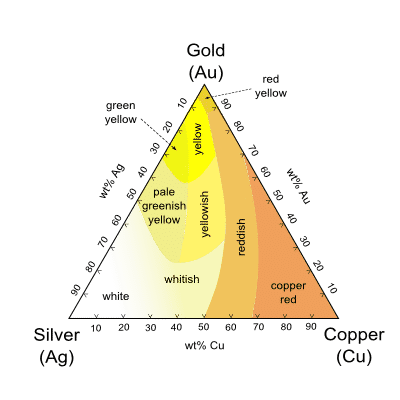

Color: Gold alloys can be customized to achieve different colors, ranging from warm reds to cool whites. The exact shade of an alloy depends on the metals used and the percentage of gold in the mixture.

Density: The density of gold alloys varies depending on their composition. For example, white gold is denser than yellow gold due to the presence of heavier metals like palladium or platinum.

Tarnish resistance: Certain gold alloys, such as white gold, are more resistant to tarnishing than pure gold. This is because the alloying metals create a protective barrier against oxidation.

Common Applications of Gold Alloys

Gold alloys find applications in a wide range of industries and products. Here are some common uses:

Jewelry: Gold alloys are extensively used in the creation of stunning jewelry. Whether it’s an engagement ring, a necklace, or a pair of earrings, gold alloy jewelry offer a perfect balance of beauty, durability, and versatility.

Dentistry: Gold alloys have been used in dentistry for centuries. Their biocompatibility, corrosion resistance, and ability to be easily shaped make them ideal for dental crowns, bridges, and other dental restorations.

Electronics: Gold alloys are widely used in the electronics industry due to their excellent conductivity and corrosion resistance. They are used to make connectors, switches, and other components in electronic devices.

Aerospace engineering: Gold alloys are used in aerospace applications due to their high strength, resistance to corrosion, and ability to withstand extreme temperatures. They are used in components such as connectors, sensors, and thermal management systems.

How are Gold Alloys Made?

The process of making gold alloys involves carefully combining gold with other metals in precise proportions. The metals are melted together to form a homogeneous mixture, which is then cooled and shaped into the desired form.

The choice of metals and their proportions depend on the desired properties and color of the alloy. For example, adding more copper to gold will create a redder alloy, while adding more silver will result in a whiter alloy.

Factors Affecting the Properties of Gold Alloys

Several factors can influence the properties of gold alloys:

Metal composition: The types and proportions of metals added to gold can significantly affect the alloy’s properties. For example, adding more copper will increase the alloy’s hardness and reddish hue.

Purity of gold: The purity of gold used in the alloy can also impact its properties. Higher purity gold alloys tend to be softer and have a richer color.

Heat treatment: Heat treatment techniques, such as annealing or quenching, can further modify the properties of gold alloys. These processes can enhance the alloy’s hardness, strength, and other mechanical properties.

Advantages and Disadvantages of Gold Alloys

Gold alloys offer several advantages over pure gold, but they also have some drawbacks. Here are some pros and cons to consider:

Advantages: – Increased strength and durability – Wide range of colors and appearances – Versatility in design and application – More affordable than pure gold – Excellent conductivity and corrosion resistance

Disadvantages: – Potential for allergic reactions in some individuals (e.g., nickel allergies) – Requires periodic maintenance (e.g., rhodium plating for white gold) – The value of the alloy is influenced by the price of gold and other metals

The Future of Gold Alloys

As technology advances and new materials are developed, the future of gold alloys looks promising. Researchers are exploring innovative ways to enhance the properties of gold alloys, such as improving their resistance to wear or developing alloys with unique properties for specific applications.

Additionally, sustainable and ethical practices in mining and refining gold are gaining importance. The industry is moving towards responsible sourcing and manufacturing to minimize environmental impact and ensure fair labor practices.

In conclusion, gold alloys have an enduring allure that stems from their ability to transform gold into a range of captivating colors and properties. From the warm glow of rose gold to the timeless elegance of white gold, these alloys have captivated artisans and scientists for centuries. Whether used in jewelry, dentistry, electronics, or aerospace engineering, gold alloys continue to play a vital role in various industries. As we look to the future, we can expect further advancements in gold alloy technology, ensuring that this magical fusion of metals remains as valuable and captivating as ever. For more visit www.aarchievgold.com